Water and soil stewardship strategy

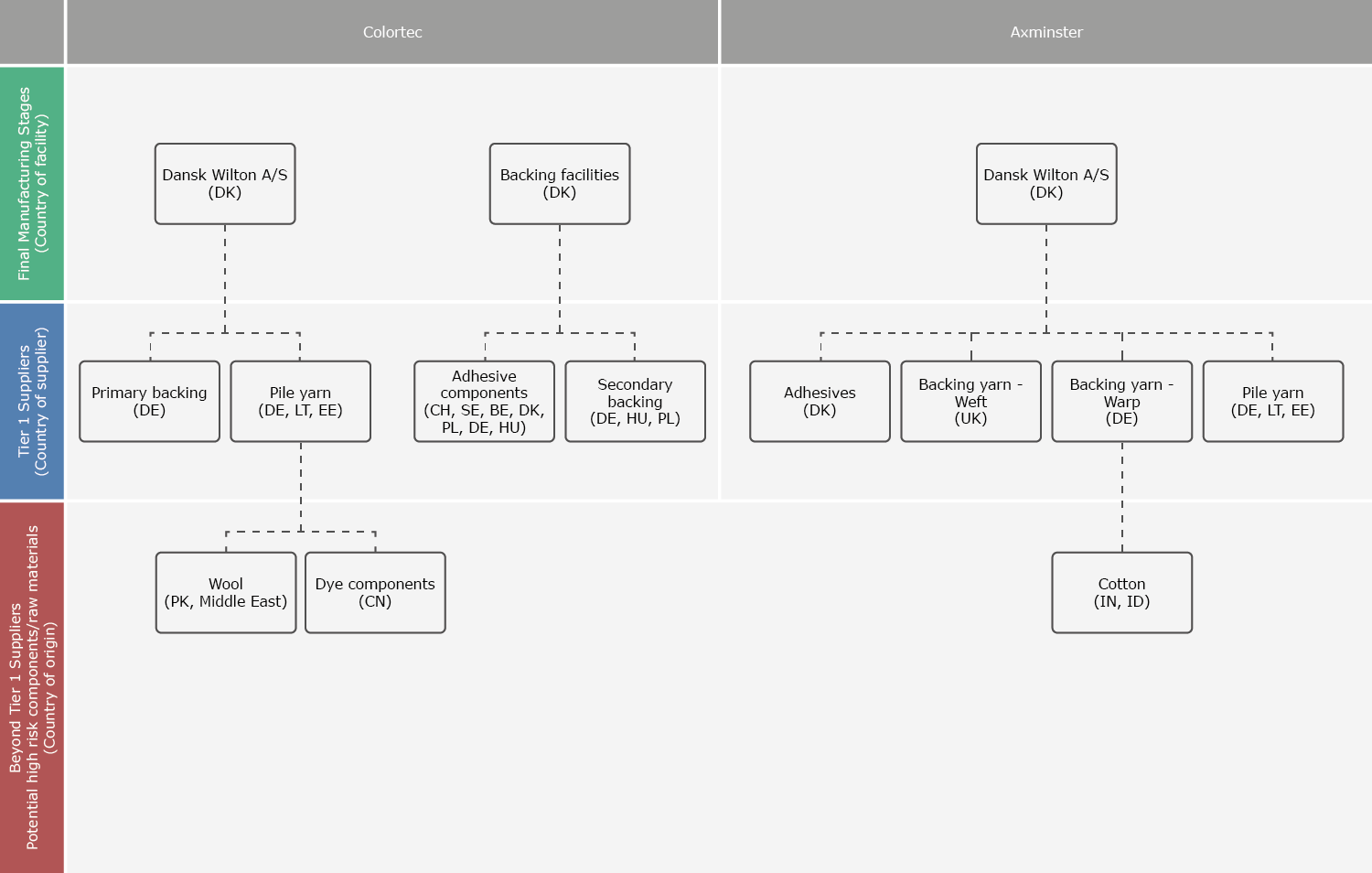

In our Water and soil stewardship strategy, we have set specific objectives related to our consumption of wool as wool is a primary resource of both Axminster and Colortec carpets manufactured at Dansk Wilton.

Wool can, by definition, contain residues of pesticides, which are used in agriculture and transferred to grazing animals. The aim of our water and soil stewardship strategy is to use certified organic wool to 100% exclude the occurrence of pesticide residues in the wool used in our carpets (and the use of pesticides in farming in general).

The aim is to be able to certify our carpets on GOLD level in the Material Health and Water & Soil Stewardship categories in our Cradle to Cradle certification.

Challenges related to certified wool:

Wool used for carpets need to have certain properties to meet the wear and tear requirements of contract use (heavy wear and tear) to ensure a good quality and hence durability. At this stage there is not much certified wool suitable for carpets used in the contract market. To our knowledge there is no GOTS certified (Global Organic Textile Standard) wool available. An option could be Ecolabel certified wool which is a focus area in our optimization dialogue with our yarn supplier.

Another challenge also affecting the certification issue is the lack of traceability in many countries producing wool: i.e. New Zealand has a structure with a limited number of very large farms supplying wool making traceability easy. Hence, the Ecolabel certified wool appropriate for carpets we have identified is New Zealand wool. In i.e. United Kingdom on the contrary, many small farms delivers wool to the wool dealers, making traceability a challenge.

These challenges are related to existing structures and systems that must be questioned and changed over time. We appreciate and support a positive and regenerative development and hope that an openness about these issues helps to address the challenges in the industry.

Despite challenges related to residual pesticides in wool, we firmly believe that wool is still a preferred fiber for carpets, as it has many great properties: Wool is inherently fire retardant, so we do not have to add fire retardant to meet strict fire requirements, wool is absorbent, i.e. absorbs and releases moisture and thus contributes to a healthy indoor climate, wool is a rapidly renewable natural fiber and wool carpets have very good acoustic properties.

Synthetic fibers have other advantages and disadvantages and are also generally associated with pollutant intensive processes, including challenges with microplastics, just as several synthetic fibers are oil-based.